Monocoque Vacuum Chambers |  Monocoque Vacuum Chamber

Monocoque Vacuum Chamber

본문

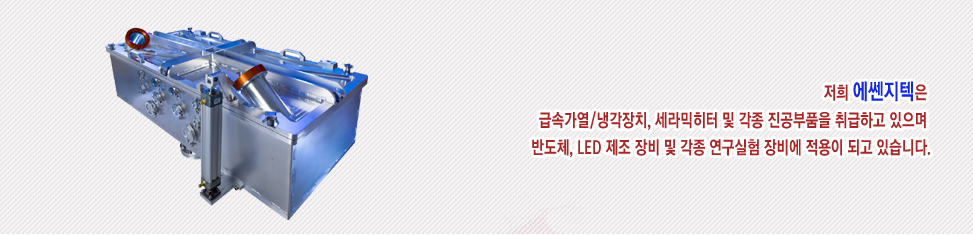

Monocoque chambers are machined from solid aluminum alloy 5000 and 6000 series billet or thick plate. Forged material is often used to eliminate the risk of vacuum leak paths entrapped by the billet forming process—other methods can use cast micro-structure aluminum. Aluminum is available in extremely thick plates (40” or 1016mm). Monocoque chambers enable internal and external machining, which can provide a high concentration of design features, a minimum surface area and a maximum surface quality without weld oxide contamination. Precise component location is achieved, because these are controlled in a single machining setup and welding related distortion can be eliminated. Elaborate internal mounting brackets and shapes can be included in monocoque chamber designs.

Atlas Technologies is the world leader in aluminum vacuum chamber engineering and manufacturing. With over 30 years experience in cutting-edge vacuum product design, we pride ourselves in providing the world's finest and most advanced UHV aluminum chamber technology. Atlas' aluminum vacuum chamber production techniques (Chamber Configurations) can be broken down into five basic categories:

Atlas Technologies is the world leader in aluminum vacuum chamber engineering and manufacturing. With over 30 years experience in cutting-edge vacuum product design, we pride ourselves in providing the world's finest and most advanced UHV aluminum chamber technology. Atlas' aluminum vacuum chamber production techniques (Chamber Configurations) can be broken down into five basic categories:

- Plate-to-Plate Chambers

- Cylindrical Chambers

- Formed Chambers

- Monocoque Chambers

- Extruded Chambers