CF Flange |  atlas cf flange

atlas cf flange

본문

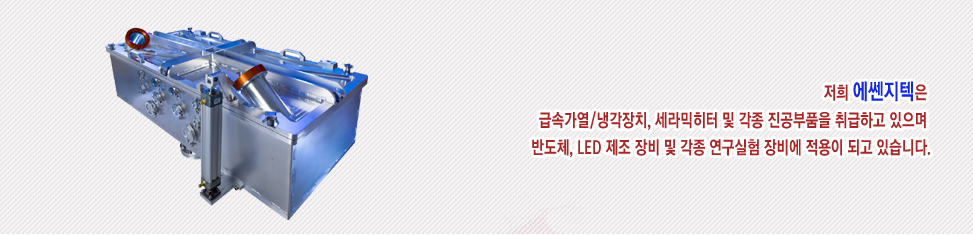

The Atlas CF™ Flange combines the time-tested reliability of the stainless steel ConFlat® (CF) knife edge, with an aluminum flange body for weld up to an aluminum chamber.

The Exceptional Vacuum Properties of Aluminum are Within Reach:The Atlas CF Flange provides standard all-metal-sealing for aluminum vacuum chambers. It enables vacuum engineers and designers to fully utilize the exceptional high and ultra high vacuum properties of aluminum. The Atlas CF™ Flange—the aluminum flange with a stainless steel knife-edge seal—makes UHV aluminum vacuum systems a reality.

Using proprietary and state-of-the-art explosion welding technology, our stainless to aluminum bimetallic flanges are fully compatible with the industry standard ConFlat® flange interface. Employing CERN’s innovative 20° back-bevel (90° included angle) knife-edge design, the Atlas CF™ Flange provides a longer service life than conventional CF flanges.

Atlas CF™ Flanges are suitable for service in vacuum levels to 1x10-13+ Torr and 250°C bakeout temperatures. Our bimetallic flanges can be easily welded to aluminum vacuum vessels and are the key to successful integration of aluminum UHV technology in your application.

Our flanges are used in prominent high (HV), ultrahigh (UHV) and extreme high vacuum (XHV) applications around the world. They find extensive use with semiconductor fabrication OEMs where superior heat conduction, chemical resistance, manufacturing ease and the lower cost of aluminum vacuum systems translate into measurable productivity and cost of ownership advantages.

Please browse the size bar and tabs above to find the right models for your application. We are delighted to manufacture any custom modifications per your specific requirements.

Application Specific Models:

Non-Magnetic Atlas CF™ Flanges: Because aluminum is essentially non magnetic Atlas manufactures a large number of vacuum chambers and flanges for low magnetic permeability applications. Atlas offers a line of Atlas flanges made with a 316LN face instead of a 316L face. 316LN has a significantly lower magnetic permeability than standard stainless steel. Even though 316LN has a lower permeability than conventional stainless it too can often not be used due to its magnetic permeability; for applications requiring even lower permeability we manufacture Atlas CF Flanges with a titanium knife edge and face instead of a stainless steel face. The titanium faced Atlas CF flanges offer an essentially non magnetic all metal seal flanges with the favorable economic and vacuum advantage of aluminum chamber.

Typical non magnetic uses are UHV synchrotron and particle physics and industrial applications, where high magnetic permeability is detrimental to beam quality or experimental results. Such applications include non-magnetic beam tubes, wigglers, undulators, free electron lasers, drift tubes, spectrometers...

Low Z, Low Nuclear Activation Atlas CF Flanges: In neutron applications such as the production of radioisotopes for medical imaging, aluminum vessels fitted with our flanges replace all stainless steel UHV systems, because residual, neutron induced, radiation in aluminum has a half-life orders of magnitude shorter than that of stainless steel (which contains Cobalt and Chrome). Our flanges enable aluminum UHV system use in cyclotrons and nuclear reactors. For such applications Atlas offers a reduced stainless face or a titanium flange face.

Light/Low Weight Atlas CF Flanges: For weight sensitive applications such as Aeronautical, Space or portable systems Atlas offers either a reduced thickness of stainless or titanium faced or a line of Atlas CF flanges. Using these models, engineers can significantly reduce overall weight. Depending on size, reduced stainless flanges are produced with a stainless interface that's about 20% to 40% thinner than standard flanges. Contact our sales department for more information on our custom bimetallic, high and ultrahigh vacuum solutions.

Explosion Welding/Explosion Bonding: Robust bimetallic joints for dissimilar metals

Atlas Technologies concentrates much effort in the development of methods and processes specifically intended for bonding dissimilar metals for use in ultrahigh vacuum (UHV) scientific and industrial applications. Atlas holds various patents in this technology, including those for the Atlas CF™ flange and the Atlas ATCR™ Face Seal Fitting/Gland.

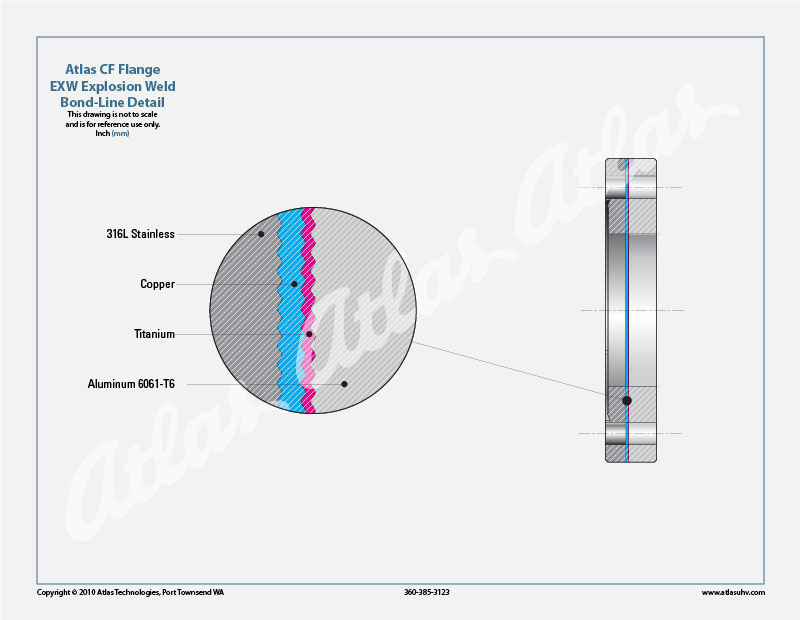

Explosion welding or bonding (EXW) is a solid state process by which dissimilar metals can be joined together at an atomic level. The bonds are very strong, fully metallurgical and ductile. Preparation for bonding requires that plates lay flat to each other, a flyer plate on top of a base plate separated by a small gap. An explosive charge is placed on the flyer plate and detonated from a point at the edge of the plate. A controlled progressive ignition travels across the flyer plate like ripples in a pond. The explosion accelerates the plates together with impact velocities of 1800~2200 m/sec. A high energy surface plasma is formed between the plates, moving ahead of the collision point and stripping electrons from the two bonding surfaces. The electron-hungry metals are then thrust together at extreme pressures forming an electron-sharing bond. Metals like copper and stainless steel can be readily bonded through the EXW process. However aluminum and stainless are metallurgically incompatible and not be directly bonded, because of the formation of brittle intermetallic compounds. Atlas has developed patented multi-layer composites technologies that provide the metallurgical compatibility required for joining aluminum to stainless and other exotic metals.

The Atlas CF™ Flange is manufactured using a multi-layered composition consisting of 316L stainless steel, copper, titanium and 6061-T6 aluminum.

The Exceptional Vacuum Properties of Aluminum are Within Reach:The Atlas CF Flange provides standard all-metal-sealing for aluminum vacuum chambers. It enables vacuum engineers and designers to fully utilize the exceptional high and ultra high vacuum properties of aluminum. The Atlas CF™ Flange—the aluminum flange with a stainless steel knife-edge seal—makes UHV aluminum vacuum systems a reality.

Using proprietary and state-of-the-art explosion welding technology, our stainless to aluminum bimetallic flanges are fully compatible with the industry standard ConFlat® flange interface. Employing CERN’s innovative 20° back-bevel (90° included angle) knife-edge design, the Atlas CF™ Flange provides a longer service life than conventional CF flanges.

Atlas CF™ Flanges are suitable for service in vacuum levels to 1x10-13+ Torr and 250°C bakeout temperatures. Our bimetallic flanges can be easily welded to aluminum vacuum vessels and are the key to successful integration of aluminum UHV technology in your application.

Our flanges are used in prominent high (HV), ultrahigh (UHV) and extreme high vacuum (XHV) applications around the world. They find extensive use with semiconductor fabrication OEMs where superior heat conduction, chemical resistance, manufacturing ease and the lower cost of aluminum vacuum systems translate into measurable productivity and cost of ownership advantages.

Please browse the size bar and tabs above to find the right models for your application. We are delighted to manufacture any custom modifications per your specific requirements.

Application Specific Models:

Non-Magnetic Atlas CF™ Flanges: Because aluminum is essentially non magnetic Atlas manufactures a large number of vacuum chambers and flanges for low magnetic permeability applications. Atlas offers a line of Atlas flanges made with a 316LN face instead of a 316L face. 316LN has a significantly lower magnetic permeability than standard stainless steel. Even though 316LN has a lower permeability than conventional stainless it too can often not be used due to its magnetic permeability; for applications requiring even lower permeability we manufacture Atlas CF Flanges with a titanium knife edge and face instead of a stainless steel face. The titanium faced Atlas CF flanges offer an essentially non magnetic all metal seal flanges with the favorable economic and vacuum advantage of aluminum chamber.

Typical non magnetic uses are UHV synchrotron and particle physics and industrial applications, where high magnetic permeability is detrimental to beam quality or experimental results. Such applications include non-magnetic beam tubes, wigglers, undulators, free electron lasers, drift tubes, spectrometers...

Low Z, Low Nuclear Activation Atlas CF Flanges: In neutron applications such as the production of radioisotopes for medical imaging, aluminum vessels fitted with our flanges replace all stainless steel UHV systems, because residual, neutron induced, radiation in aluminum has a half-life orders of magnitude shorter than that of stainless steel (which contains Cobalt and Chrome). Our flanges enable aluminum UHV system use in cyclotrons and nuclear reactors. For such applications Atlas offers a reduced stainless face or a titanium flange face.

Light/Low Weight Atlas CF Flanges: For weight sensitive applications such as Aeronautical, Space or portable systems Atlas offers either a reduced thickness of stainless or titanium faced or a line of Atlas CF flanges. Using these models, engineers can significantly reduce overall weight. Depending on size, reduced stainless flanges are produced with a stainless interface that's about 20% to 40% thinner than standard flanges. Contact our sales department for more information on our custom bimetallic, high and ultrahigh vacuum solutions.

Explosion Welding/Explosion Bonding: Robust bimetallic joints for dissimilar metals

Atlas Technologies concentrates much effort in the development of methods and processes specifically intended for bonding dissimilar metals for use in ultrahigh vacuum (UHV) scientific and industrial applications. Atlas holds various patents in this technology, including those for the Atlas CF™ flange and the Atlas ATCR™ Face Seal Fitting/Gland.

Explosion welding or bonding (EXW) is a solid state process by which dissimilar metals can be joined together at an atomic level. The bonds are very strong, fully metallurgical and ductile. Preparation for bonding requires that plates lay flat to each other, a flyer plate on top of a base plate separated by a small gap. An explosive charge is placed on the flyer plate and detonated from a point at the edge of the plate. A controlled progressive ignition travels across the flyer plate like ripples in a pond. The explosion accelerates the plates together with impact velocities of 1800~2200 m/sec. A high energy surface plasma is formed between the plates, moving ahead of the collision point and stripping electrons from the two bonding surfaces. The electron-hungry metals are then thrust together at extreme pressures forming an electron-sharing bond. Metals like copper and stainless steel can be readily bonded through the EXW process. However aluminum and stainless are metallurgically incompatible and not be directly bonded, because of the formation of brittle intermetallic compounds. Atlas has developed patented multi-layer composites technologies that provide the metallurgical compatibility required for joining aluminum to stainless and other exotic metals.

The Atlas CF™ Flange is manufactured using a multi-layered composition consisting of 316L stainless steel, copper, titanium and 6061-T6 aluminum.